Six Reasons Lithium-ion Batteries Work Better for Pallet Jacks than Traditional Power Sources

Lithium-ion batteries are gradually replacing older battery technologies in a variety of applications. When it comes to material handling and electric walkie pallet trucks in particular, the switch is happening for a number of compelling reasons.

1. No Need to Water Lithium-Ion batteries

Lead acid batteries require regular watering to maintain battery health. Watering is required because when lead-acid batteries charge, water in the electrolyte splits into hydrogen and oxygen, creating explosive dangerous gas that must be ventilated. This process, along with evaporation, lowers water levels in the battery. If the water is not replaced and the battery stays in use, it causes damage and reduces the battery life. In addition,

overfilling the battery creates a risk of acid spills, a messy and dangerous business.

Lithium-ion batteries, on the other hand, are completely sealed and require no watering. Charging and cell balancing is monitored by the battery management system so equalization charges are never needed and no dangerous gasses are ever generated under normal use.

2. Lithium-Ion Batteries Charge Faster

Battery charge times vary depending on battery capacity, chemistry, and charger output. Lead acid batteries produce a substantial amount of heat when charging and require a ‘cooldown’ period afterward. A typical charge/use cycle for lead acid is 8 hours use, 8 hours charge and 8 hours rest/cooldown. In contrast, a typical charge cycle for a lithium-ion battery could be 8 hours use, 1 hour charge, and 8 hours use (no cooldown needed). This allows the battery to be used continuously, while charging during breaks and lunch.

When running two or three shift operations, lead-acid batteries must be swapped out for charging and cooldown, meaning additional batteries are needed as well as storage areas with ventilation for dangerous gases. In contrast, with lithium-ion batteries running your fleet of walkie pallet jacks, you do not need to swap batteries nor do you need ventilated charging / storage areas.

3. Say Goodbye to Acid and Lead Contamination

Acid spills and lead contamination have adverse impact to industries such as food processing, grocery, pharmaceutical and beverage delivery. No company wants walkie pallet jacks to be a source of contamination for their products or employees. By shifting from lead acid to lithium-ion batteries, you no longer need to worry about acid spills and lead contamination.

4. Lithium-ion Lasts Longer

Lithium-ion technology is widely used in portable electronic devices because it provides long runtimes, and has superior cycle life. Pioneers in the lithium-ion sector for industrial applications, such as Flux Power, are taking the benefits of lithium-ion and applying them  to material handling applications. The overall life of lithium-ion batteries for pallet jacks last 3-5x longer.

to material handling applications. The overall life of lithium-ion batteries for pallet jacks last 3-5x longer.

Runtime testing has shown that lithium-ion batteries have dramatically increased runtimes when compared to lead-acid. A Flux LiFT Pack lithium-ion battery in an electric walkie pallet jack runs 45% longer than similarly rated (amp-hour) lead-acid batteries. This coupled with fast charging capabilities equals less downtime and greater productivity.

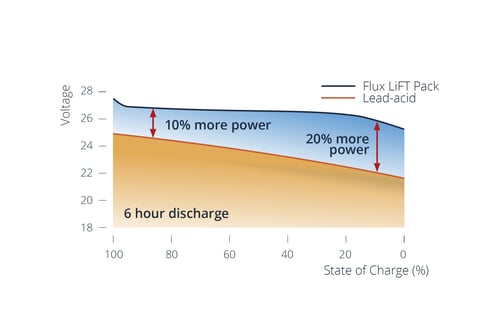

5. Lithium-ion Batteries Are More Powerful

Lithium-ion batteries have flat discharge curves and provide higher constant power compared to lead-acid. This basically means that you can continue using your lithium-ion powered pallet jack without annoying sluggishness as the battery drains. Keeping your inventory moving and workers happy.

6. Simple Switch to Green Technology

There are numerous benefits when converting to lithium-ion technology, including the simple fact that lithium-ion is a more ‘green’ solution, with zero emissions, no lead, and no acid. The chemistry is also more efficient, meaning you’ll be using up to 30% less energy, reducing CO2 emissions. The batteries also last longer, meaning you’re using 3-5x fewer batteries, further reducing CO2 emissions.

The batteries are weighted to meet minimum truck requirements and can weigh a couple hundred pounds. A solution like the Flux LiFT Pack is plug and play. So you can convert an existing fleet of lift truck lead-acid batteries without any conversion kit required. Simply disconnect your old battery, lift and replace with your new lithium-ion battery to begin using a more convenient, productive and cost-effective power source.

%20(1).png?width=1080&height=1080&name=Lithium-Ion%20VS%20Lead%20Acid%20eBook%20(Menu%20Visual)%20(1).png)

%20(1)-3-1-1-1-1.png)